The Australian manufacturing industry has undoubtedly contracted when compared to other booming sectors in the past two years. Due to this fact, many manufacturers are leading their industries by implementing more efficient and automated systems to not only support their individual growth but to allow them to scale without increasing overheads in an industry where margins are falling.

While MRP software has been around since the 1960’s and has gone through generations of technology upgrades, and system advances, its core the business use case of the software is still to increase efficiencies in ordering and procurement, streamline workflows on the shop floor, and provide more accurate data around demand and supply planning. Manufacturers with a single system that supports their businesses from end-to-end have a strong market differentiator. These innovating companies can get a clear picture of past, current and future performance and make educated decisions that ultimately save time, money and resources.

Australian manufacturing industry’s undeniable decline.

Over the past ten years, Australia has seen an undeniable decline in the performance of manufacturing compared to other industries. What does this mean for key Australian industry players that are exporting to Asia and Pacific region?

It means that businesses in this market need to pioneer new and better ways of managing their customers, their accounting, their systems and their operations, or they will face continued erosion of their bottom line.

A paper by economists Georgeson and Harrison, states that manufacturing is still an essential part of the Australian economic growth plan. It produces $100 billion of output each year, ranking sixth among ANZSIC industries. Manufacturing accounts for over 930,000 jobs. The manufacturing industry is in the middle of a much-needed structural change, as it is in most developed economies.

However, we still see a decline in overall output in percentage terms. This lower percentage does not mean the industry is falling; it only shows that it is growing less than the rest of the economy. Therefore, there is a door open for manufacturers that want to differentiate in their business from the competition.

Manufacturing and exporting are rebalancing says economist Julie Toth: “In the last ten years, Australia switched to produce more consumables and fewer heavies.” There are growth pockets in products and services including food, beverages, groceries, specialist machinery, pharma, cosmetics, vitamins, supplements, building materials, textiles and furniture.

23% of the industry had moved to Advanced Manufacturing by 2013. Advanced Manufacturing or Industry 4.0 is the ability of companies to capture customers’ needs and transform them into products quickly through the use of integrated systems, sensors and technologies.

These leading companies combine the competitive advantages of a multidisciplinary team and digital transformation. The market niches in which they compete have low volumes. These smaller niches require a specialised service that offers quick response, cost-and value competitiveness and after-sales support.

China, South Korea and Japan need support to fulfil their demand for efficient buildings, sustainable energy, and new transport infrastructure. These cities offer excellent international trade opportunities for innovative manufacturers.

The specialisation of the industry will lead the way in manufacturing for Asia and Pacific markets. Australian’s technology and engineering skills can respond to the region’s rapid urbanisation. Over the next decades, there will be an incremented demand in the Asia trade for specially-designed and custom goods. Gregory O’Brien, Australian Government’s labourer, in his paper “Australia’s trade in figures,” said eight of our top ten markets are in the Southeast Asia region: China, Japan, South Korea, India, New Zealand, Singapore, Malaysia and Taiwan.

Australia’s top ten export markets.

- 1. China. AU$ 91 297 millions 28.8%

- 2. Japan. AU$42 355 millions 13.4%

- 3. United States. AU$22 114 millions 7.0%

- 4. South Korea. AU$20 014 millions 6.3%

- 5. India. AU$3 574 millions 4.3%

- 6. New Zealand. AU$12 577 millions 4.0%

- 7. Singapore. AU$11 044 millions 3.5%

- 8. United Kingdom. AU$8 815 millions 2.8%

- 9. Malaysia. AU$7 966 millions 2.5%

- 10. Taiwan. AU$7 479 millions 2.4%

Technology relieves complexity and supports exporting through automation and systemisation.

Companies exporting to the Asia Pacific region know well that the process takes time and requires high and continual investment. If supported by robust domestic demand, exporting it’s a noble path of growth with a substantial return.

The export path requires strategic controls that allow managers to lead and adjust the supply chain quickly to different market demands. Australian Business models may be unfitting in other countries for cultural, regulatory, and other reasons.

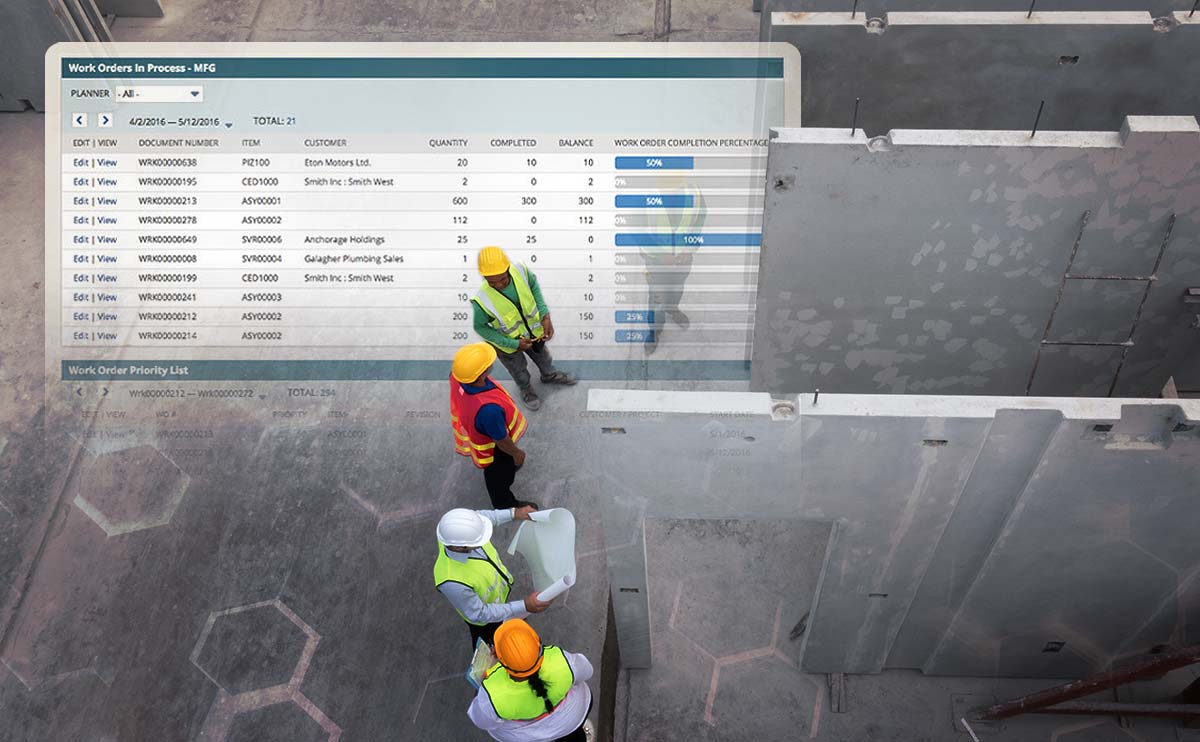

Modern cloud systems provide levels of control and flexibility that have not been easily achievable in legacy on-premise MRP solutions. These systems improve operational efficiencies and provide a robust framework to ensure the business can grow and expand, while still have full visibility on the overall performance of each area of the company.

ERP systems are essential for any business that is wanting to scale in the manufacturing sector. With the complexities that arise when considering the transactional relationships between inventory, procurement, panic and preventative maintenance, multi-location warehousing and distribution, foreign currencies, taxes, laws, languages and many other global preferences.

“Manufacturing businesses should focus on centralising their data in the cloud and making it easily accessible by users in different locations and satisfying different roles and responsibilities within the organisation.” Said Klugo’s consultant, Michale Dean.

Companies with systems operating in silos will spend countless resources on communication technology to connect their databases with APIs and integration. While these types of solutions may get to the point where they are working, there will always be added risk with an increase in the number of software vendors a business’s needs to deal with on a day to day basis. Also, the ability to report across siloed systems means data is rarely live, and often inaccurate.

In contrast, Cloud ERP solutions, such as NetSuite provide a single platform technology which eliminates the need for integrations, offers live and accurate data and does it in a way designed for delivery over the internet.

Investing in dynamic systems from the start gives a manufacturing company an edge over the competition in an increasingly competitive space. It is smarter to start with the right platform than trying to move into it in the future.

Also, for modern manufacturers involved in exporting, ERP software provides a lot of digitally transformative opportunities to automate and simplify global trade and investment with full automation and support of multi-company, multi-entity, multi-currency and multi-language requirements.

NetSuite has customers all over the world, and a particularly strong following in manufacturing from the European Union, Hong Kong, and Southeast Asia.

NetSuite Manufacturing Edition is a fully featured solution to cater to the needs of a growing manufacturer. The platform provides a single solution that includes:

- Sales and CRM Management.

- Accounting and Financial Control.

- Advanced Inventory and Demand Planning.

- Warehouse Management.

- Import-Export

- MRP functionality to manage Work Orders.

- Complex WIP and Routings.

Need a specialist’s free advice?

NetSuite has thousands of clients all around the world, who have made extensive use of the sophisticated functionality that is on offer for a growing manufacturer. To find out more about how NetSuite can support your growth, contact Klugo today.