Allcon

Croydon South, Victoria, AUS

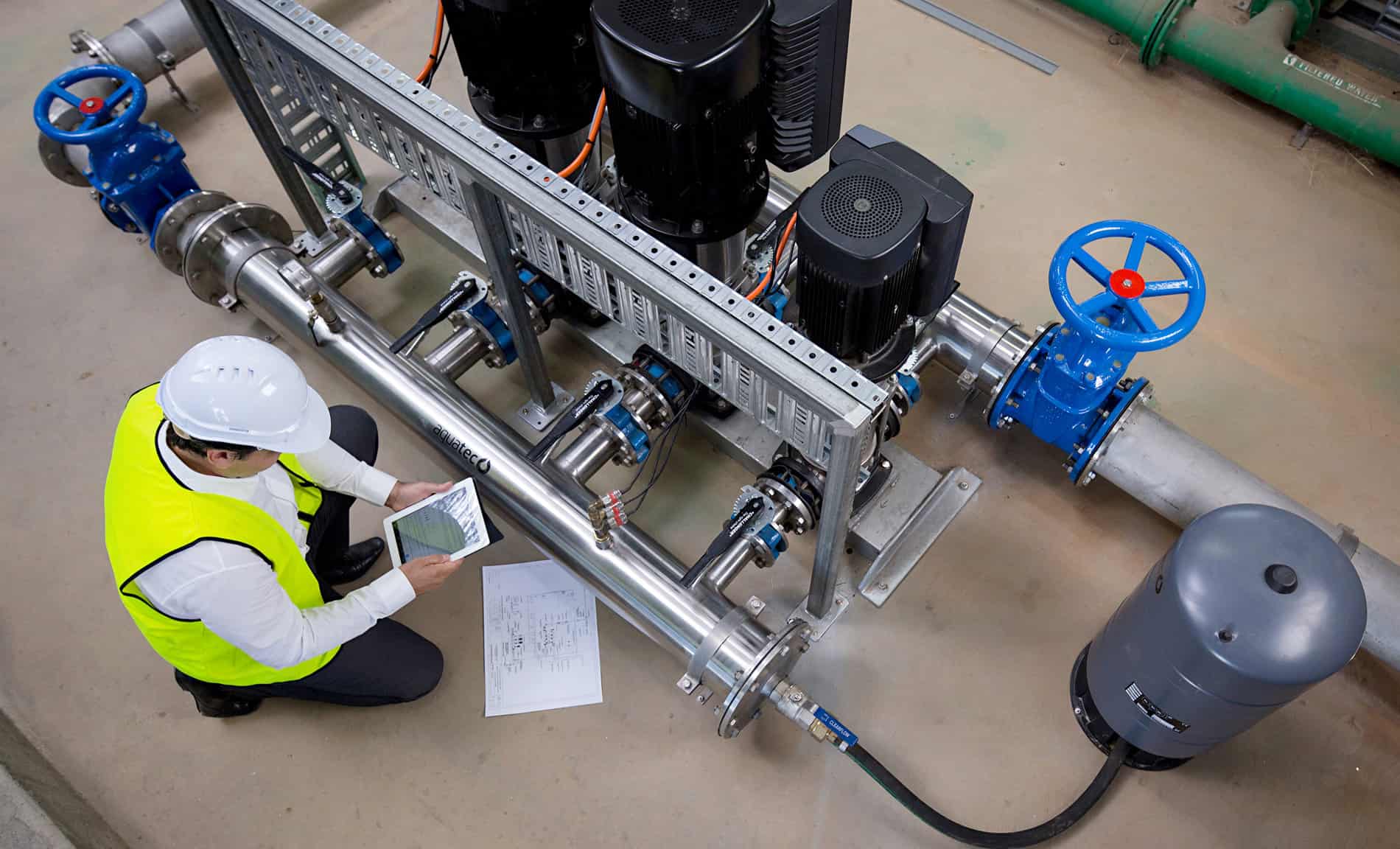

About Allcon

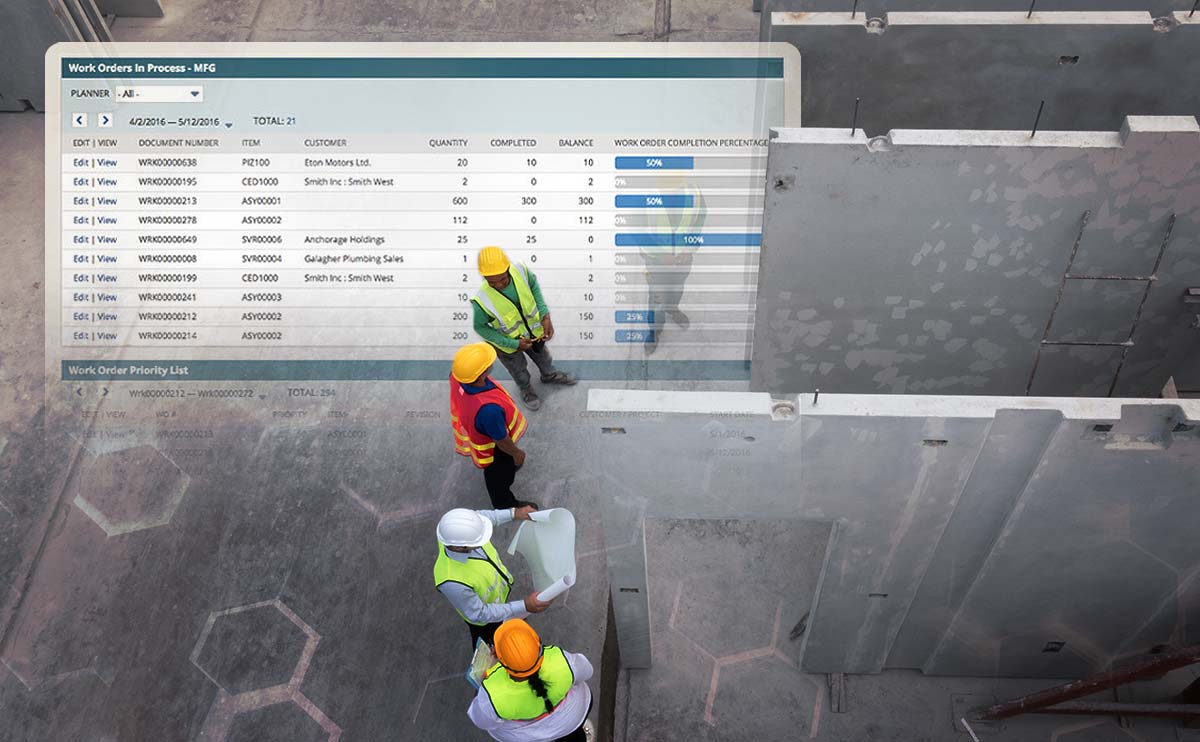

SuiteCommerce Advanced was an obvious choice for Allcon as they are already experienced NetSuite users. Having one system that is fully integrated will enable Allcon to maximise their business efficiency as well as create a better customer experience.

Challenges Faced

Harvey Weeks Marketing Manager at Allcon, said their B2B website lacked integration with their current business systems.

“A significant challenge was the lack of integration between our existing website and SuiteCommerce Advanced. The website was the only business system that was ‘outside’ Netsuite,” says Harvey.

Allcon’s 3 FTE customer service staff would process up to 150 phone orders per day – they needed a solution to help divert customers online and free up these resources and allow the business to grow.

Business Requirements

This new eCommerce site would need to achieve the following:

- Ensure it’s easy and fast for customers to order

- Reflect the Allcon premium delivery service with freight calculations

- Ability to save orders and come back within a set period

- Ability to review past orders and reorder

- Ability to order items on backorder

- Ability to lookup order status

- Purchases done with credit card payment – (EziPay payment gateway).

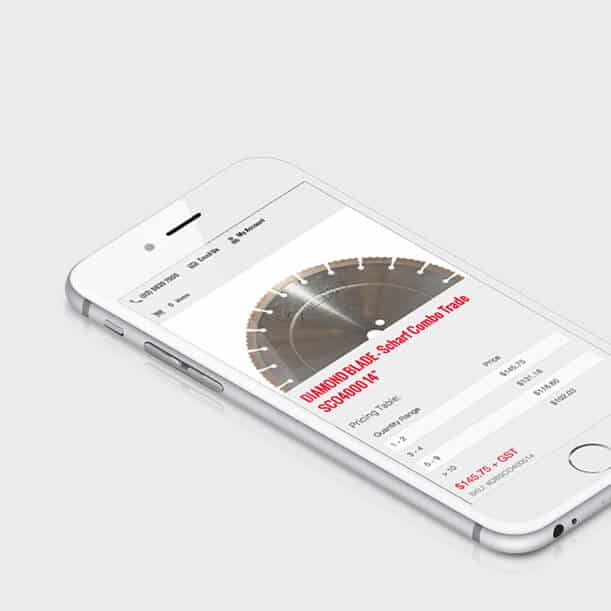

Due to the nature of their businesses, a high percentage of Allcon’s customers also access the website when on site at a job – with up to 40% of website views coming via mobile device. A key requirement was for the website to be fully responsive across any device and allow Allcon’s customers to find product information quickly and place orders no matter where they were.

“The website will continually grow and evolve with the business, as we take on new product ranges and geographical locations. The Klugo team have been excellent to work with.”

Business Requirements

This new eCommerce site would need to achieve the following:

- Ensure it’s easy and fast for customers to order

- Reflect the Allcon premium delivery service with freight calculations

- Ability to save orders and come back within a set period

- Ability to review past orders and reorder

- Ability to order items on backorder

- Ability to lookup order status

- Purchases done with credit card payment – (EziPay payment gateway).

Due to the nature of their businesses, a high percentage of Allcon’s customers also access the website when on site at a job – with up to 40% of website views coming via mobile device. A key requirement was for the website to be fully responsive across any device and allow Allcon’s customers to find product information quickly and place orders no matter where they were.

Business Improvements

“Importantly, customers love our new website! Our efficiency has been improved in a number of ways – including management of products etc. on the website, and from the fact that existing customers are now purchasing online rather than by phone, which leaves us more time to do more important things such as selling to new customers,” says Harvey.

Now a customer can place an order online, and this goes straight to despatch. Previously, the customer had to phone in and we manually entered the order.

“The website will continually grow and evolve with the business, as we take on new product ranges and geographical locations,”

“The Klugo team have been excellent to work with.” he says.

For more information on Allcon, visit their website here.